Sustainable production

Reducing our carbon footprint with recycled packaging

Copyright © Artempo Bespoke, recycled packaging Alfred de Musset once said, “the bottle doesn’t matter, as long as you get...

Read the article

ARTEMPO

Case study December 20, 2023

Copyright © Artempo

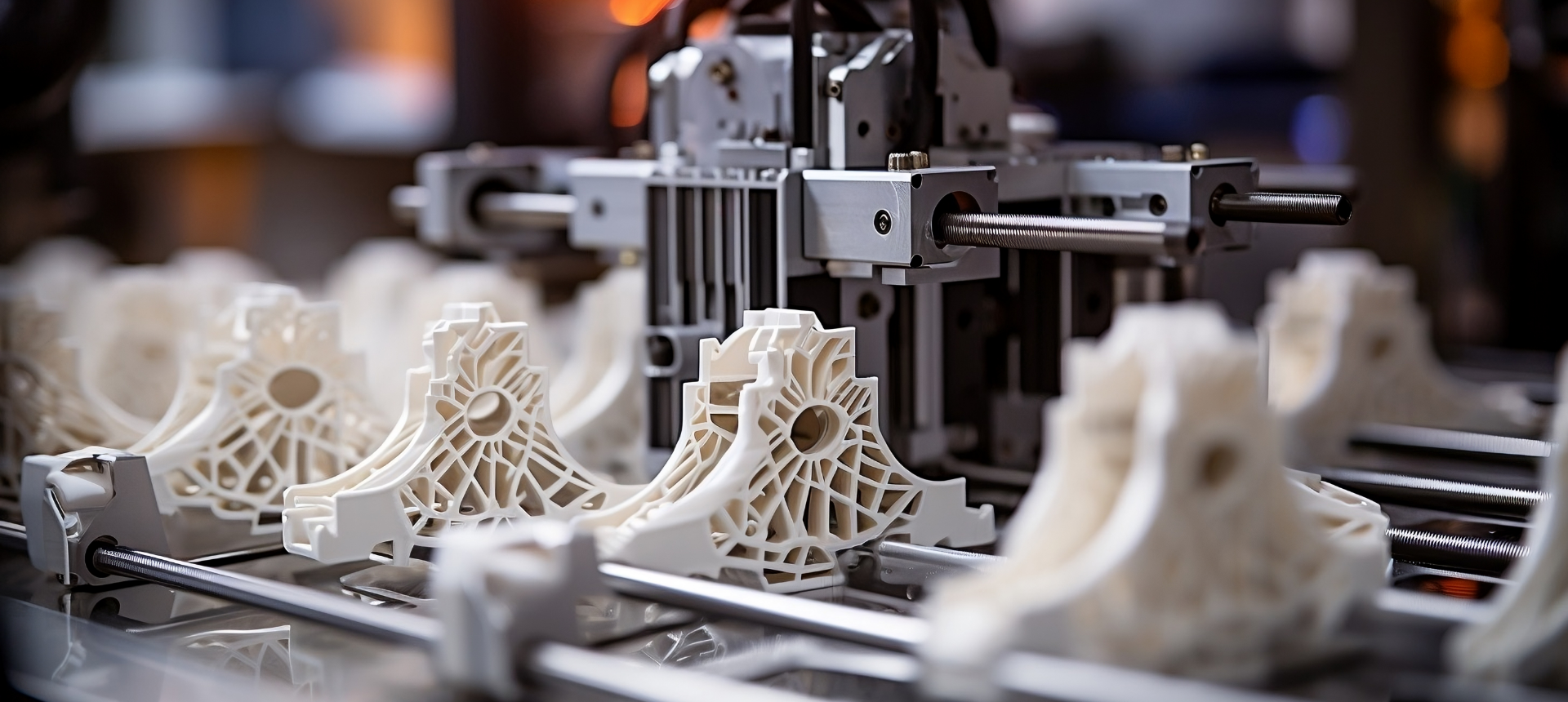

Often associated with plastics, 3D printing is much more complex and varied than you might think. Invaluable for high volume custom parts, we extensively use this production technique for our awards and tombstones. So, it was vital that we could find sustainable 3D printing solutions that respected the environment. And that’s exactly what we’ve done, since the materials used for 3D printing have come a long way in recent years. The 3D-printing we currently use at ARTEMPO is based on organic materials. We 3D print using oyster shells, wood shavings, corn starch and coffee grounds! So, the materials we use are natural, sustainable, and recyclable.

Copyright © Artempo

The recycled filaments we use are made from plastic waste. It is then shredded and turned into granules. Afterwards, these same granules are heated and extruded to become filament.

There are currently several 3D printing processes. In each, the part is first modelled in CAD software and then prepared in a slicing or cutting programme before being sent to a machine for assembly.

One of the most widely used processes is called fused deposition moulding (FDM). In the form of a coil, the filament is heated by an extrusion head and then deposited on a heated plate in successive layers to build the part to exact volume. This technique enables us to develop awards and tombstones in a wide range of natural and recyclable materials.

Another technique used by Artempo is Powder Bonded Printing or 3DP. In this process, mineral powder is spread in a layer on a plate and then a binder solidifies the material in the desired locations. In a second step, ink is directly applied to the hardened powder. Excess powder is then reused to avoid waste.

In addition, two other materials are extensively used: PA11 HP, a powdered material derived from castor beans, which is biodegradable and exceptionally strong. The parts are printed in monochrome. Finally, mineral powder can be used to print multicolour parts in a material made from gypsum, which is a dehydrated calcium sulphate, similar to plaster and therefore recyclable.

Copyright © Artempo

Sustainable production

Copyright © Artempo Bespoke, recycled packaging Alfred de Musset once said, “the bottle doesn’t matter, as long as you get...

Read the article

Prize-giving ceremonies

Great Place To Work®, a key player in well-being at work Great Place To Work® supports organizations in managing quality...

Read the article

Non classé

ARTEMPO Universe : harmony at work In today’s world of work, a company’s success is measured not only by its...

Read the article

Fields marked with * are required

Fields marked with * are required